Repair & Calibration Services

Melt Indexer Plastometer

Tinius Olsen is thrilled to introduce the latest member of our melt indexer series, the MP1200. This model surpasses the standards of Procedure A and also meets the criteria of Procedures B, C, and D of ASTM D1238, serving a broad spectrum of needs. We continue to support our previous models, the MP-600 and the MP 993 units.

Pressure Calibration

TOU Pressure calibration offers services for most pressure instruments.The calibration provided by our lab uses test equipment standards traceable to the National Institute of Standards and Technology (nist). Our Client portal provides copies of your current and past calibration certificates as well as all current standard calibration records used in your procedure.

Temperature Instrument Calibration

Tinius Olsen Used Equipment provides calibration services for a wide range of portable temperature instruments. The calibrations are conducted in a temperature lab using test equipment that is traceable to the National Institute of Standards and Technology (NIST). The available calibration types for temperature instruments include: J, K, T.

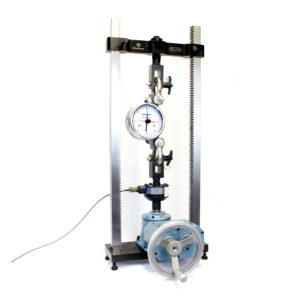

King Brinell Repair and Calibration

When servicing or repairing the Test Head, it is recommended that all severely worn parts be replaced with new ones. For older machines, periodically inspect the test head for oil leakage around moving parts, packing nuts, and set screws. Should excessive oil leakage be observed, it is typically necessary to replace the packing and change the hydraulic oil.

Torque Wrench/Device Calibration

Calibration of torque wrenches is conducted in the TOU Torque lab. In such a laboratory, professional calibrators conduct tests, repairs, and adjustments on torque wrenches and similar tools. They ensure the torque wrenches are calibrated to a precision within a 1% to 6% margin of error. Calibration is carried out by a skilled technician who uses a device capable of generating an accurate reading to compare against the torque wrench's measurement.

LOAD Devices Repair and Calibration

When servicing or repairing the Test Head, it is recommended that all severely worn parts be replaced with new ones. For older machines, periodically inspect the test head for oil leakage around moving parts, packing nuts, and set screws. Should excessive oil leakage be observed, it is typically necessary to replace the packing and change the hydraulic oil.